Recent Projects

Check Out Some of Our Recent Projects...

External review of drill and blast operations was undertaken between 25 November and 5 December 2022. The review focused on both on-bench practices and drill and blast design.

Main outcome was the assessment of the controls applied to critical level risks to determine whether current level controls can be stiffened with higher hierarchy level controls.

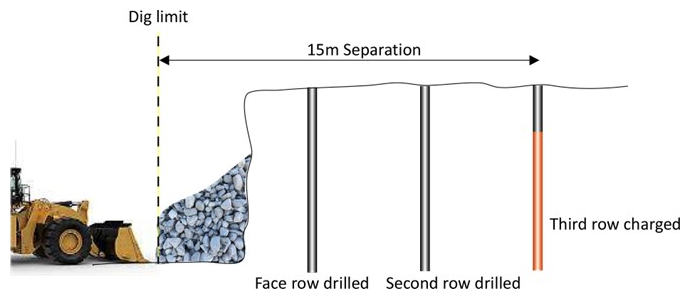

The 2023 PhuBia Mining audit of the drill and blast operation covered the following elements:

- System audit of the standardised high-level plans

- Compliance audits of all drill and blast operations across both sites PKM and BHX covering the following 21 elements

- Blast Master Management

- Blast Standards Management

- Drill and Blast Concept

- Drill Pattern Design

- Charge and Tie-Up Design

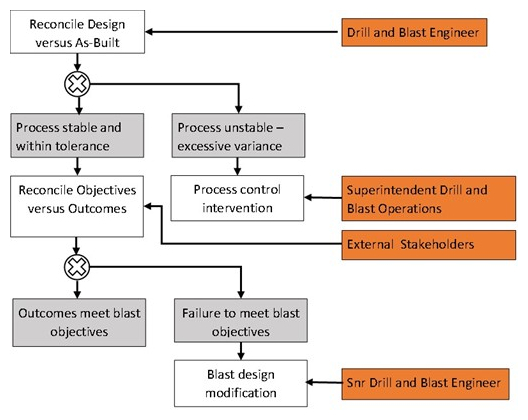

- Reconcile Design vs As-Built

- Reconcile Objectives vs Outcomes

- Drill Bench Acceptance

- Drilling Operations

- Prepare for Charging

- Explosives Charging

- Tie Up

- Blast Clearance and Firing

- Blast Incident Management

- Misfire Recovery

- Class 1 Explosives Storage

- Class 1 Explosives Transport

- Class 5 Materials Storage

- MMU Operations

- Class 1 Explosives Procurement

- Bulk Explosives Procurement

BMI has drafted a full set of high-level drill and blast standards and specifications that will be delivered in eight languages across the various sites.

Specifications specific to surface operations as well as underground production, development and coal were completed.

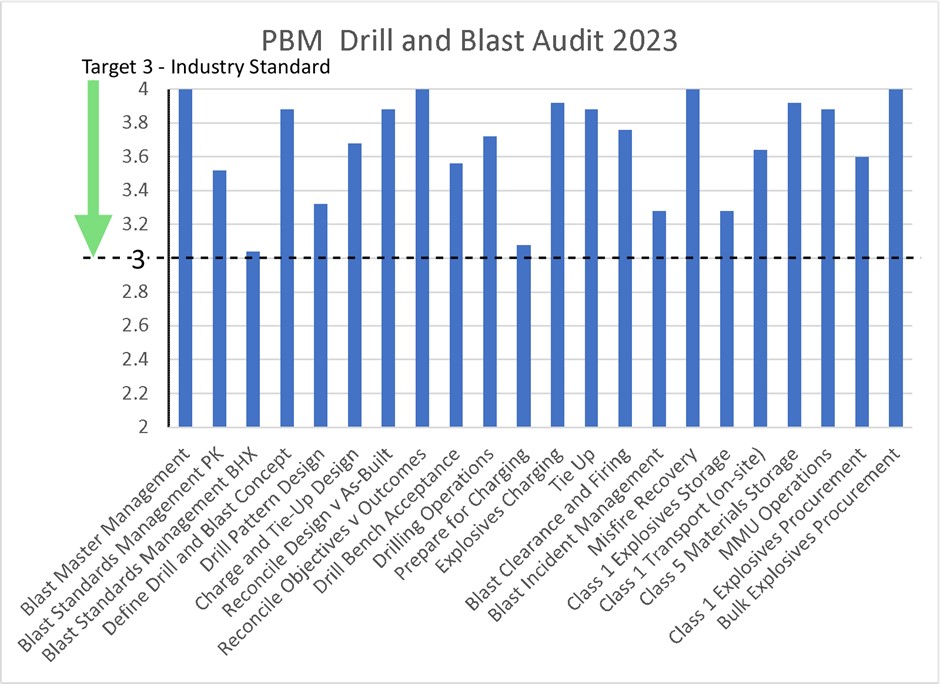

Risk assessment using BowTie analysis were applied to the identified high consequence outcomes:

- Unplanned detonation in operations

- Unplanned detonation in storage and transport

- Flyrock

- Loss of explosives security

- Persistent adverse blast outcomes

BMI provides ongoing support to OT in regards produciotn drill and balst for the development of the block cave.

This is the fourth block cave we have been involved with since firing the first electronic drawbells at Cullinan back in 1988.

Current work was around drawbell brow control using near field vibration modelling. We had used this previously at Argyle with good results.

Standardisation and stabilisation with a particular focus on Statistical Quality Assurance and Quality Control over the key drill and blast parameters.

The ability to calculate delivered blast hole diameter in soft materials by reconciliation of charge mass and volume enabled greater charge accuracy and forward planning.

Staff training to recognised competency standards was provided to all blast crews, supervisors and shotfirers as part of the process.

Single shot stope assessment

BMI has provided an assessment of the feasibility of firing production stopes as a single shot firing.

Single shot firings have significant benefits:

- Elimination of prep, cleanout and redrill of remaining holes caused by previous firings.

- Interim stope stability issues are avoided.

- Reduced production disruptions caused by multiple firing.

- Reduction in worker exposure to working against open holes below.

The main risk with single shot firings is where the void ratio is compromised leading to stope freezing and the creation of bridges. This can result in stope failure and significant loss of production.

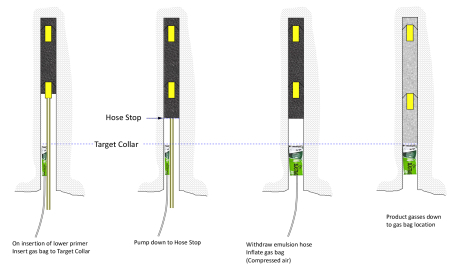

Single shot stope firings have been widely used in block caving where blind uphole drawbells are reliably fired using dynamic material flow to provide the required void.

Whilst the footprint and volume of a typical drawbell is less than the current planned stope limits, the technique for delivery of fluidised flow is applicable.

Soft Ground Fume Investigation

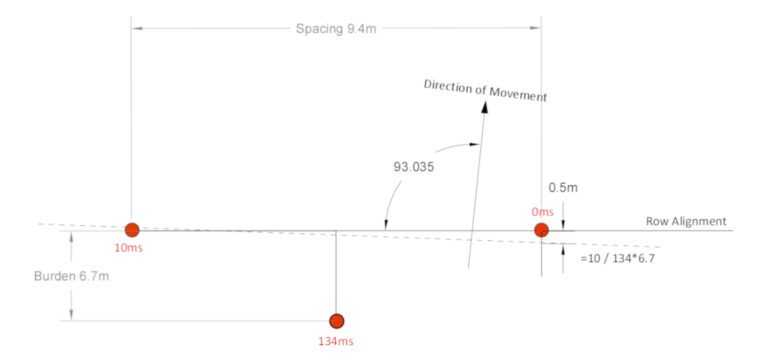

The review of blast history looked for correlations between fume generation and geology, explosives products, powder factors, design, timing and relief. The main correlation was found to be relief.

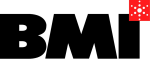

This resulted in a set of design standards being documented to ensure blast relief is maximised.

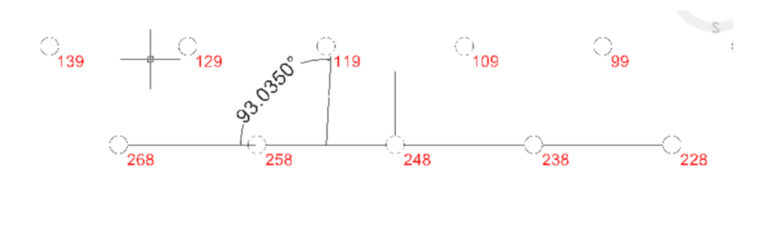

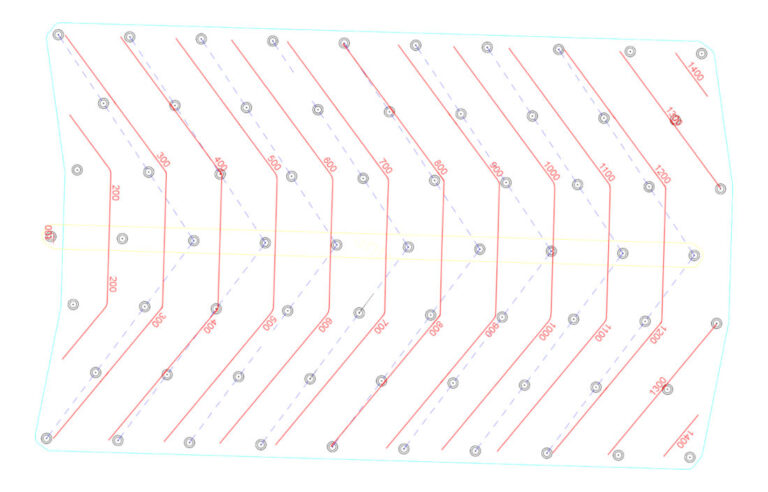

The standards are based on row by row firing toward the dynamic void using specific drilling and timing geometry.

A modification to the spacing to burden ratio to increase relief was also defined.

In this instance the calculation for the angle between the row alignment and the DoM is

Angle = ATAN (Spacing Timing / (Burden Timing x Burden) / Spacing) + 90

= ATAN (10/134* 6.7 / 9.4) + 90

= ATAN (0.5/9.4) + 90

= 93.035 degrees